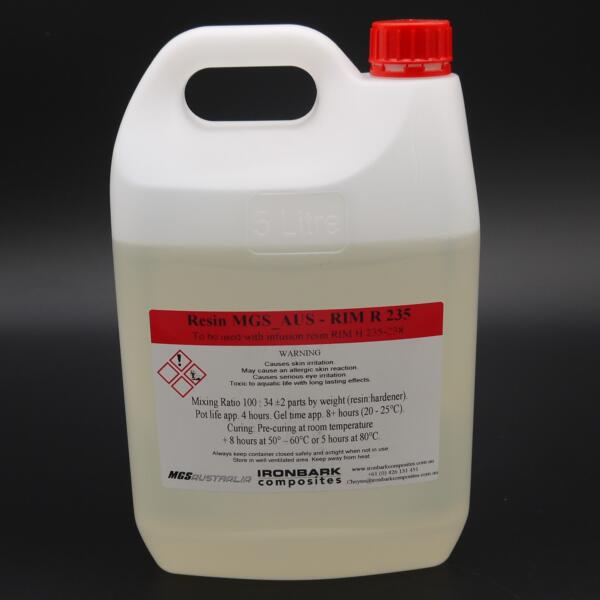

Westlake Epoxy Resin L235 Part A

Laminating resin system approved by the German Lloyd. It contains no solvents and fillers and has a wide range of pot lives. The system is used for processing of glass, carbon and aramide fibres, featuring high static and dynamic loadability. This system has very good adhesion properties on wood and other materials. In boatbuilding, laminating resin L 235 can be used universally, especially for wood-epoxy constructions. The range of pot lives is between approx. 10 min. and more than 12 hours.

Parts produced with L 235 result in high-gloss and non-tacky surfaces, even with unfavourable curing conditions, e.g. lower temperatures and/or high humidities. The mixing viscosity guarantees a fast and complete impregnation of the reinforcement fibres, however, the resin will not spill out of the fabrics on vertical surfaces.